Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

purlin roll forming machine

Fansy Sun

Contact person

Basic Information

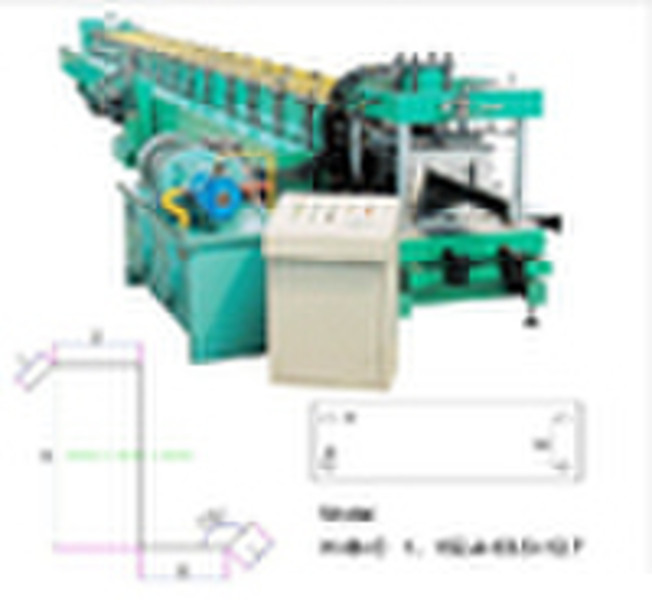

purlin roll forming machine brief introduction This production line consists of decoiler, feeding, guiding and leveling system, punching system, pre-cutting system, roll forming system, finished product rack, electric control system and hydraulic system. The working flow can be fnished automatically. technical data NO.ItemParametersRemarks1Suitable MaterialtypeSteel coilThickness(mm)2.0-3.0Subject to customers requirements and final designYield strength (Mpa)235MPa/355MPawidth(mm)See profile drawing2Forming speed (m/min)10-15Excluding punching and cutting time3Forming stationsAbout 14 stepsSubject to final design4Forming main motor power (KW)15Subject to final design5Main machine hydraulic station power (KW)5.5Subject to final design6Total power (KW)20.5Subject to final design7Electricity sourceAC380V,50Hz,three phaseSubject to final design8Dimension (L×W×H)m23×2.4×1.5Subject to actual machineWorking flow: decoiler→feeding and guiding→leveling→sizing and punching→cutting→roll forming→finished product rack For more details,please do not hesitate to contact Ms Sindy. Mob:+86-132 0801 0152 trademanager:cn200019298

Delivery terms and packaging

Packaging Detail: the main machine we adopt naked packing but will be fiexed well in container with iron wire so as to prevent any damnification.The rollers will be covered by plastic film,electric control case will be in paper box, and spare parts or small parts will be in wooden box. Delivery Detail: 60 days after seller's receipt of 30% down payment

Port: Shanghai/ Ningbo

Payment term

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: